Ọ bụrụ naefere ọlaa na-eji ogologo oge eme ihe, elu nke efere ọla ahụ ga-aghọ ihe siri ike, ọ pụkwara ime ka efere ọla ahụ oxidize, nke ga-emetụta ịnọgide na-eji efere ọla.Ichacha efere ọla ahụ nwere ike ime ka ọ dịkwuo mma n'elu efere ahụ, yana O nwekwara ọrụ mgbochi oxidation, yabụ kedu usoro nhazi nke efere ọla?Kedu ihe a ga-akpachapụ anya mgbe ị na-asachapụ?

1. Brass efere polishing usoro

1. N'oge ọrụ polishing, kwadebe ihe ngwọta na-arụ ọrụ na-arụ ọrụ ọla kọpa kwesịrị ekwesị dị ka ntụziaka ahụ si dị, ma gbalịa ịrụ ọrụ ya na ebe ikuku na-ekpo ọkụ na ụlọ okpomọkụ, ka ọ ghara imetụta mmetụta ojiji nke ngwọta polishing.

2. Mgbe ị kwadebere ihe ngwọta na-egbuke egbuke ọla kọpa, gbanye efere ọla na ngwọta na-egbuke egbuke, wepụ efere ọla ahụ mgbe minit 2-3 gasịrị, tinye ya ozugbo na mmiri dị ọcha maka ihicha, ma hichaa mmiri mmiri fọdụrụnụ.

ọgwụ na workpiece iji zere emetụta ụdi ojiji.

3. Mgbe efere ọla na-egbuke egbuke ma kpochaa, ọ nwere ike ịbanye na usoro ọzọ iji fesa na passivate efere ọla.Iji gbochie efere ọla ahụ ka ọ ghara ịgbanwe agba mgbe ọ na-egbuke egbuke, ọ dị mkpa iji kpoo ikuku ma na-agafe efere ọla n'oge.

4. N'oge usoro polishing, ọ bụrụ na achọpụtara na gloss elu nke efere ọla anaghị emezu ihe ndị a chọrọ, enwere ike ịgbakwunye ihe mgbakwunye kwesịrị ekwesị na ngwọta polishing.Usoro onunu ogwu nke mgbakwunye bụ 1%-2% nke ngwọta polishing mbụ.Ihe mgbakwunye bụ ịgbaso obere ego ọtụtụ ụkpụrụ.Ọ bụrụ na ọ ka na-emezughị ihe achọrọ mgbe ọ gbakwụnye ihe mgbakwunye ahụ, ọ dị mkpa ka e jiri onye na-emepụta ihe ọhụrụ dochie ya.

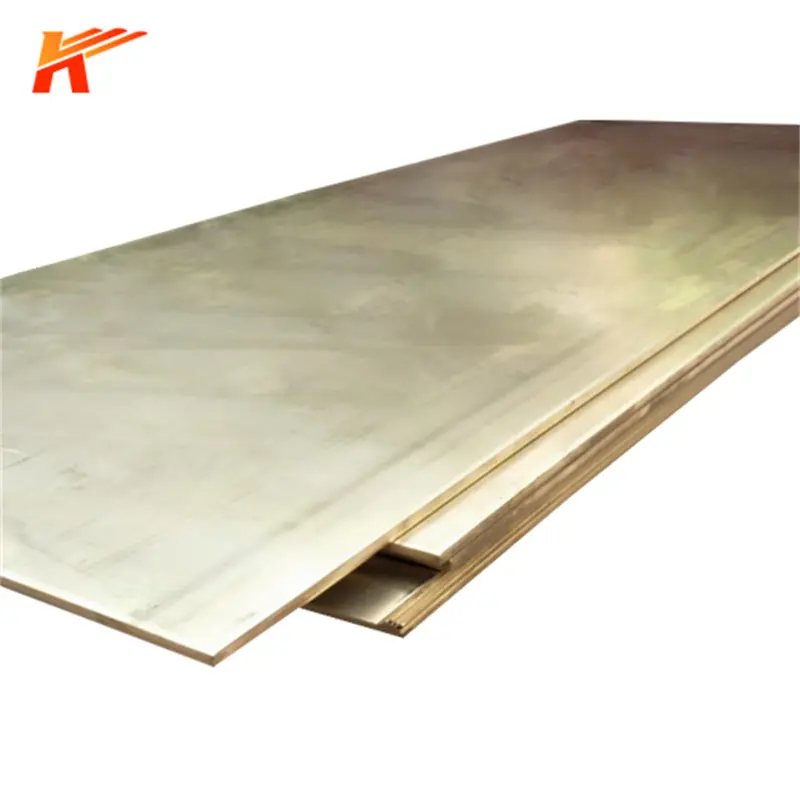

efere ọla

2. Akpachara anya maka polishing efere ọla

1. Gbalịa iji tankị plastik pp maka tankị na-arụ ọrụ nwere mmiri mmiri na-egbuke egbuke, ma ejikwala ígwè, seramiiki na tankị ọrụ ndị ọzọ.

2. N'oge usoro polishing, ṅaa ntị na ịma jijiji ma ọ bụ na-atụgharị workpiece iji gbochie overlapping elu nke workpiece na-na ezi kọntaktị na-arụ ọrụ mmiri mmiri.

3. Mgbe polishing, workpiece enweghị ike polished nke ukwuu n'otu oge, na a ụfọdụ ọdịiche kwesịrị hapụrụ n'etiti workpieces iji zere ogbenye polishing mmetụta.

4. Mgbe emechara polishing, a ga-ehichapụ ọgwụ mmiri fọdụrụnụ iji zere imetụta mmetụta ya n'oge usoro ọzọ.

5. Mgbe ihichachara, tinye efere ọla na ebe dị jụụ na ikuku maka nchekwa.

6. Mmiri na-egbuke egbuke na-emebi emebi ruo n'ókè ụfọdụ.N'oge a na-arụ ọrụ, ekwesịrị ịkpachara anya iji chebe mmiri mmiri site na kọntaktị na akpụkpọ mmadụ.Jikwaa nke ọma ka mmiri ghara ịfesa.

7. Mgbe polishing kemịkalụ, ọ dị mkpa iji mee ọgwụgwọ nchebe n'oge.Tinye n'ime ihe nchebe ọla kọpa maka sekọnd 30, nke nwere ike melite nguzogide oxidation nke efere ọla.

Oge nzipu: Mar-03-2023