Iberibe ọlanwere ezigbo plasticity na ike dị elu, ezigbo igwe, ịgbado ọkụ dị mfe, ma kwụsie ike megide corrosion izugbe.Eriri ọla bụ ọla kọpa na zinc, aha ya bụ maka agba odo ya.N'ezie, e nwere ọtụtụ ụdị nke brass ibe n'ahịa, dị ka H96, H90, H85, H70, H68, wdg N'isiokwu a, ndị editọ ga-eme ka ị ghọta mmalite nke ndị a ụdị na ihe yiri ya:

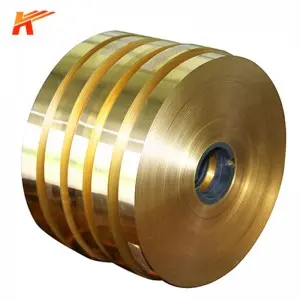

eriri ọla

1. Arụmọrụ nke H90 brass strip yiri nke H96, mana ike ya dị ntakịrị elu karịa nke H96.Enwere ike iji ígwè kpuchie ya ma kpuchie ya na enamel.

Na-eji: mmiri na igbapu ọkpọkọ, ihe nrite, ihe osise, eriri tank, na ibe bimetallic.

2. H85 brass strip nwere ike dị elu, ezigbo plasticity, nwere ike iguzogide okpomọkụ na nhazi nrụgide nke ọma, ma nwee ezigbo ịgbado ọkụ na nkwụsị corrosion.

Na-eji: ọkpọkọ na-ekpochapụ ọkụ na ikpo ọkụ, ọkpọkọ siphon, ọkpọkọ serpentine, na akụrụngwa jụrụ oyi.

3. H96 brass strip nwere ike dị elu karịa ọla kọpa dị ọcha, ezigbo conductivity thermal conductivity and electric conductivity, elu corrosion resistance na ikuku na mmiri ọhụrụ, na ezigbo plasticity, dị mfe na oyi na-ekpo ọkụ nhazi nrụgide, dị mfe weld, forge na tin-plated. , enweghị nchekasị Ọ na-adịkarị mfe mgbawa corrosion.

A na-eji ya eme ihe: A na-eji ya dị ka conduits, ọkpọkọ condensation, ọkpọkọ radiator, ikpo ọkụ, eriri mmiri ụgbọ ala na akụkụ ndị na-eduzi n'ichepụta igwe n'ozuzu.

4. H70 na H68 brass nwere ezigbo plasticity na ike dị elu, ezigbo machinability, mfe ịgbado ọkụ, nnọọ kwụsiri ike na n'ozuzu corrosion, ma na-adịkarị mfe corrosion na cracking.A na-eji H68 eme ihe na bras nkịtị.A na-agbakwunye otu ụdị dị iche iche, H68A na obere arsenic (As), nke nwere ike igbochi bras site na nsị ma melite nguzogide corrosion nke ọla.

Na-eji: mgbagwoju oyi stamping na miri stamping akụkụ, dị ka radiator shells, conduits, bellows, katrij case, gaskets, wdg

Oge nzipu: Jan-10-2023