Ọla kọpa deoxidized site na Phosphor Rod

Okwu mmalite

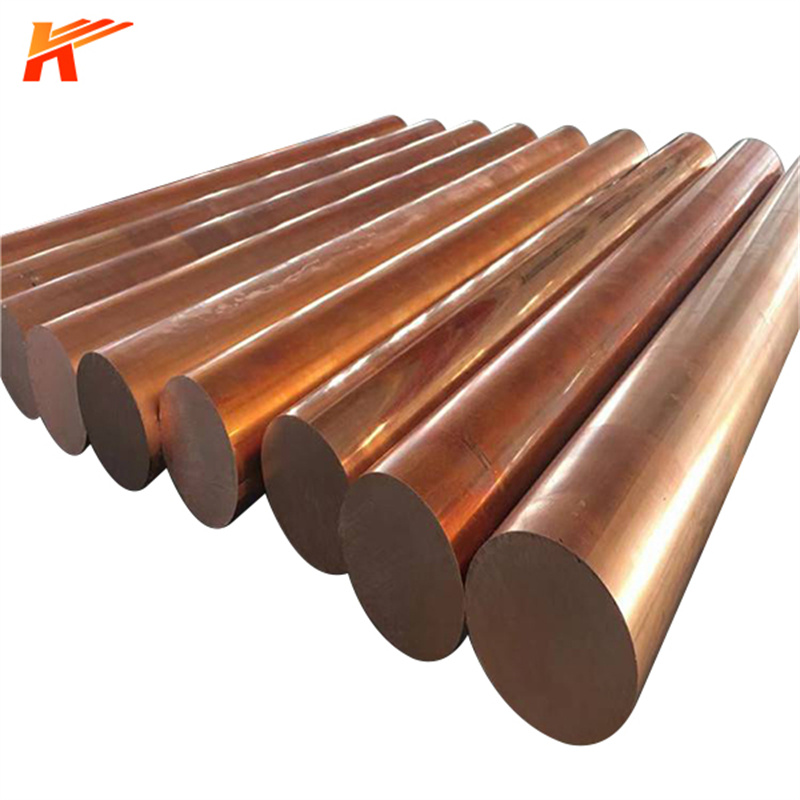

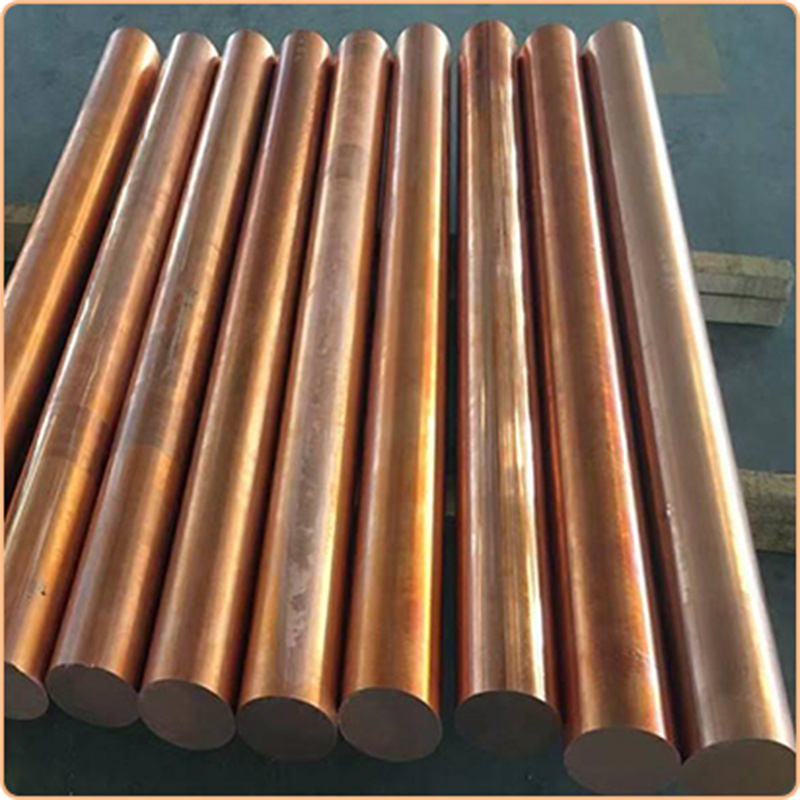

Phosphorus deoxidized ọla kọpa mkpanaka nwere ezigbo thermal conductivity, corrosion eguzogide na magburu onwe processability, mfe idi mma punching, agbatị, iwe iwe riveting, igwakorita, circling, miri punching, na-ekpo ọkụ forging na ịgbado ọkụ nhazi.A na-ejikarị alloy emezigharị maka inye mmanụ dị iche iche, ọkọnọ mmiri, pipeline gas, akụkụ eserese miri emi na akụkụ ịgbado ọkụ.

Ngwaahịa

Ngwa

A na-ejikarị ọla kọpa phosphorous deoxidized eme ihe na ngwa ọkpọkọ, mana nwekwara ike ịbụ efere, warara ma ọ bụ mkpanaka, ọkọnọ waya.Ejiri ya dị ka mmanụ ụgbọala ma ọ bụ gas na-ebufe ọkpọkọ, ọkpọkọ mmiri, ọkpọkọ condensate, ọkpọkọ m, condenser, evaporator, okpomọkụ mgbanwe, akụkụ igbe ụgbọ oloko.

Nkọwa ngwaahịa

| Ihe | Mgbanaka ọla kọpa na-eme ka phosphorus |

| Ọkọlọtọ | ASTM, AISI, JIS, ISO, EN, BS, GB, wdg. |

| Ihe onwunwe | TP2,Cu-DHP,C12100,C1220,CW024A,SF-Cu,C106,Cu-b1, wdg. |

| Nha | Enwere ike ịhazi nha dịka mkpa ndị ahịa si dị. |

| Elu | igwe igwe, na-egbu maramara, na-egbuke egbuke, mmanụ, ahịrị ntutu, ahịhịa, enyo, mgbawa ájá, ma ọ bụ dị ka achọrọ. |

Dee ozi gị ebe a ziga anyị ya